In this paper, I turn to how the press captured this latest transformation of its mode of production. I have also discussed how periodicals conceive of themselves as both ephemeral and archival forms. In my previous work I have considered the interplay between fixity and change that characterises periodical publication. And finally, I note how many articles remark on the distinctive sound of the machines, the ‘click, click, click’ of their operation so evocative of a ticking clock. I attend to the role of the hot metal itself, now rendered the primordial form of language. For instance, in many accounts of the process compositors became machine like, providing input, while the machines seemingly regulated themselves. I look at how human agency was represented as reconfigured. I outline how images were used to make the process meaningful. My paper takes this double focus – the page as material record of the process the text as description of it – and uses this to consider how hot metal composition was introduced to readers. The pages of newspapers and periodicals are both the products of the printing process and records of it. Instead of sorts in the case, metal manifestations of the constituent units of language, there was only illegible molten metal. In each case the printing matrix was ephemeral, but the hot metal process challenged the idea that the elemental units of printing were the letters of the alphabet. However, whereas in traditional letterpress printing compositors worked in a condition of scarcity, setting type from cases with a limited number of sorts, hot metal composition took place in a condition of limitless excess as sorts were cast anew for each job. All letterpress printing is ephemeral, type and furniture locked up just long enough to print the edition before being redistributed and used for something else. The alloy is also used in factories and industries for jobs like pipe bending and constant temperature bath.In my paper I consider how late nineteenth-century periodicals and newspapers captured the new processes of hot metal composition. Since its discovery, this alloy has been used for making useful articles like fire sprinklers. Then expands again between 55° to 35☌.Īpart from being a highly efficient fusible solder, Rose metal has diverse usefulness. Rose metal contracts slightly when cooling from 80☌ to 55☌.

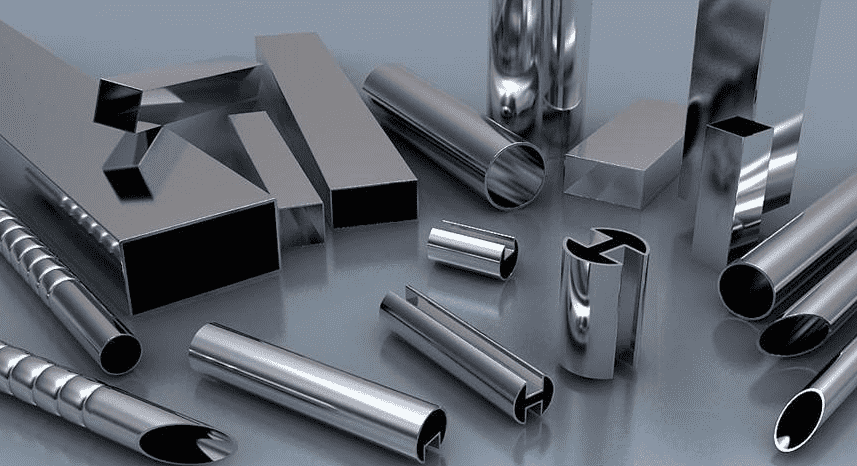

Even though fusible alloys are usually eutectic (the property of being solidified at a lower temperature than others compositions), the Rose metal alloy is not.Rose metal has a very low melting point of 212☏.It was also used to secure iron railings and balusters in stone steps and stone bases.The valve, having a low melting point, melts in fire and provides water to stop the fire from spreading. This metal is also used as a valve element in automatic fire sprinklers.Rose metal can also be used as a low temperature casting metal.It is employed only in hot bath with temperatures above 220☌. It is usually not used for the process at lower temperatures. In a constant temperature bath, the Rose metal alloy is used as a heat transfer medium.When the tube attains the desired shape, the Rose metal is re-melted and poured out of the tube. The solidified Rose metal inside the tube prevents it from getting collapsed.

Then, in the third stage, the bending of the tube is completed. In this process, the tube to be bent is first filled with melted Rose metal.

0 kommentar(er)

0 kommentar(er)